Wear parts / Consumables

For trouble-free operation of our resistance welding machines the following topics must be taken care of:

Electrodes

Because of the long delivery times of the used metals electrodes always have to be ordered early.

Since the material is very hard and so brittle there always is a risk of mechanical damage. Therefore spare electrodes always should be available at the machine. Further we recommend not to change material or shape of our electrodes without prior consultation, because they are usually defined by us and we can not give any guarantees for a good welding process then.

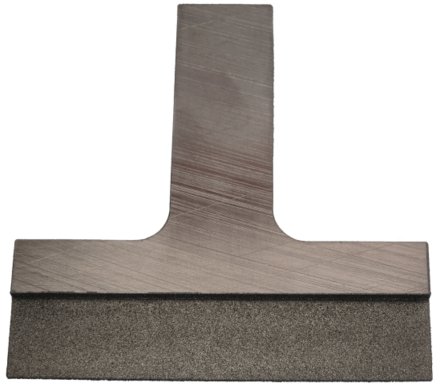

Diamond grinding plates

To clean the electrodes between welding operations, we recommend the use of our proven diamond grinding plates. They are mounted on the system near the welding tool, so that the electrodes are guided by the mechanics over the grinding plates and thereby cleaned.

These grinding plates are available in various diamond sizes (grain sizes) depending on the type or level of contamination.

Also longer delivery times must be taken into account for this, since the diamond coating is a multi-step process and must be planned accordingly.

Since the cleaning effect diminishes with regular use - the diamond coating settles or is worn away - these parts must be replaced regularly. To reduce costs, it is also possible to re-coat worn plates - if undamaged.

Cooling water system / Cleaning

For filling the cooling system we recommend our CORAGARD (R) coolant. This ensures trouble-free and low-maintenance cooling.

Also possible is tap water without any additives. Since there often residues like mud or limescale occur inside the cooling system we recommend a regular flushing using a cooling system cleaner to be obtained from us.

Calibration

To check and document the compliance of the preset parameters we recommend an annual check and maintenance of the welding components by us. Here all important values are checked using calibrated measuring devices and the successful check documented with a protocol.